The strategic approach to expanding a manufacturing lab needs proper planning and execution for success. Production laboratories must adjust their facilities because industries are expanding while technological innovations and changing compliance requirements emerge. Highly designed expandable laboratories enable firms to grow their operations while reducing major operational interruptions. The following guide presents methods to construct an establishment that supports permanent development alongside performance and product quality standards.

1. Designing for Future Expansion

Planning with a Growth Mindset

Before starting a lab design process, consider long-term requirements instead of only present needs. Businesses must evaluate changing production needs during the following five to ten-year period. Productivity expansion becomes simpler through design flexibility, which prevents the need for major renovations that lead to facility reconfiguration during periods of increased production.

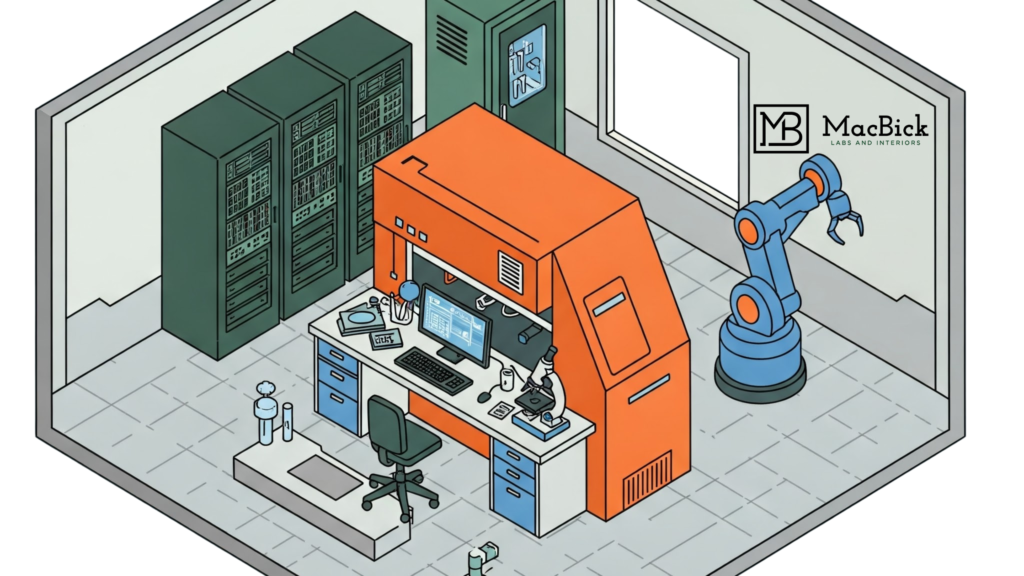

Implementing Modular Workstations

Workstations built with modularity give organizations the capability to grow. These flexible configurations enable teams to rearrange their lab areas per process changes, thus enabling facilities to adapt to new work methods and personnel and different equipment requirements.

Creating Expandable Infrastructure

An infrastructure system is mandatory for labs to support business growth. Engineers should incorporate suitable electrical systems with plumbing and ventilation elements to handle future equipment requirements and automated technology needs. Forward planning these components decreases operational downtimes and eliminates future upgrade expenses.

2. Implementing Scalable Technology and Automation

Leveraging Automation for Efficiency

Effective automation helps scale operations within laboratories. Automated instruments with robotic systems and AI-enabled quality control systems boost operational speed and remove operator mistakes. The developed technologies enable consistent operation and speed up processes which become vital for higher production volumes.

Utilizing Cloud-Based Lab Management Systems

Cloud-based Laboratory Information Management Systems (LIMS) use infrastructure in the cloud to simplify operations involving data collection reporting and workflow monitoring. These systems merge smoothly with digital equipment to provide distant access while supporting live interdepartmental collaboration no matter how many locations operate labs.

Investing in Future-Proof Equipment

The process of choosing lab equipment should include evaluation of scalability features. Select equipment that accepts software updates alongside modules and system interface capabilities. Your lab’s future competitiveness will stay strong thanks to this approach which avoids the need for buying new equipment at high costs during technological advancements.

3. Space Optimization for Increased Capacity

Maximizing Floor Space Utilization

Lab expansion requires proper space management techniques. Vertical storage systems together with mobile work areas and well-designed compact laboratories enable greater capacity enhancement that avoids requiring physical property development. Thoughtful layout planning both reduces pointless empty areas and develops efficient work routes.

Creating Dedicated Zones for Efficiency

Laboratories require a systematic arrangement that separates areas based on research requirements as well as testing requirements and production support functions. The organization system brings operational efficiency while reducing risks from cross-contaminants so new teams or equipment installations proceed smoothly.

Enhancing Workflow with Lean Principles

Implementing lean principles in laboratory design eliminates wasted efforts to produce efficient workflow systems. Standardized procedures along with minimal movement allow laboratories to cope with higher work volumes while maintaining both speed and accuracy levels.

4. Regulatory compliance and quality control are essential for lab expansion and growth.

Adapting to Evolving Industry Regulations

Labs that increase their operations need to maintain their adherence to demanding regulatory criteria. Buildings designed with compliance in mind at their start enable new spaces to avoid causing non-compliance problems. A routine review system and audits allow laboratories to monitor upcoming regulatory changes.

Implementing Scalable Quality Control Measures

The expansion of a laboratory requires ongoing maintenance of superior testing quality. Modern monitoring tools digital data tracking and document management systems reduce mistakes while making processes trackable. Quality control standards should be developed with strong mechanisms to guarantee consistency between testing and production processes.

Training Teams for Scalable Operations

The expansion of a laboratory beyond basic infrastructure needs a qualified staff in addition to physical capabilities. An organization maintains its employees’ technological expertise through continuous training that includes updates in safety regulations and industry best practices. Excellent employee training enables teams to adjust smoothly to modifications, thus maintaining continuous operations, which allows the growing laboratory to function correctly.

Conclusion

Strategic foresight paired with adaptable design and innovative commitment leads to the successful creation of laboratories that scale their manufacturing and production capacities. Future growth will become efficient for labs by implementing plans for development and integrating advanced technologies alongside space optimization and strict quality control protocols. A properly designed and expandable research lab improves operational effectiveness while decreasing expenses and creating a foundation for business growth in a dynamic industry.

Book Your Complimentary Lab Audit Today

Is your lab ready for future growth? Our expert team can assess your current setup and identify opportunities for scalability. Book a lab audit today to ensure your facility is optimized for efficiency, compliance, and expansion. Schedule your consultation now.